Products

Degasifiers series

General

YWCT has the technical ability to design and build degasifiers or air strippers to remove volatile organic content (VOC).

For projects of up to 3,000 m3/hr, cylinder FRP degasifiers are a perfect fit. The vessel in most cases is made of fiberglass reinforced with orthophtalic, isophthalic or vinylester, resins. Fire-retardant and UV-resistant supplements are standard. The vessels comply with British standard (BS 4994) and the American ASTM D 3299-81. Water distribution is carried out using an array of pipes and gravitational nozzles. Air is forced into the vessel by two axial fans in order to minimize energy cost. The PVC fill, fans, motor units, and distribution system are installed at YWCT’s premises and the system is sent to the job site as a PlugN’Play assembly.

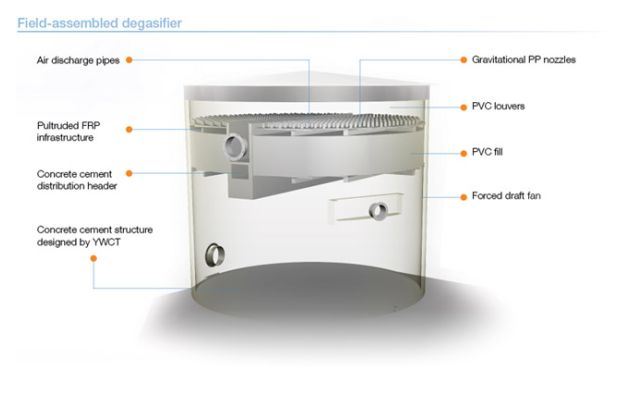

For large-scale projects (e.g., desalination plants), air strippers made of concrete cement are the best solution, as their atmospheric distribution systems minimize the required head pump and energy cost, while the effective PVC fill reduces the size of the required tank. Forced-draft centrifugal fans blow air into the degasifier. YWCT provides its customers with scale drawings of the concrete cement structure, including locations and production drawings of all pipe fittings in 2- or 3-D. While construction is taking place, all relevant parts are being purchased or manufactured and sent to the job site. When the structure is ready, YWCT’s assembly teams install the degasifier or air stripper on site, furnishing it with fill, fan, and motor unit until it is operational.

Typical gases to be removed

Amonia (NH3), Benzene (C6H6), Chlorine (CL2), Carbon Dioxide (CO2), Hydrogen Sulfide (H2S), Methane (CH4), Nitric Oxide (NO), Sulphur Dioxide (SO2), Trichloroethane, Vinyl Chloride and Xylene

Features

- Pultruded FRP hand rails and ladders

- Up to 99.8% gas removal

- Turnkey project

Type

Counterflow

Fabrication

Factory-made or Field Assembled

Material

Concrete or FRP

Air Flow

Forced draft

Water Flow

6 - 20,000 m³/hr

PRINT

PRINT